Vacuum Die-Casting

Advanced Casting Technology for Superior Quality Components

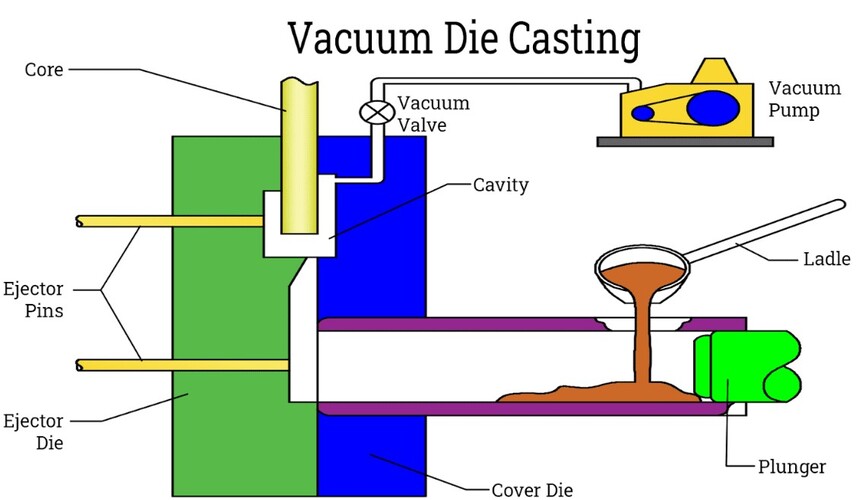

Vacuum Die Casting is a high-performance casting process that enhances the quality of die-cast parts by removing air and gases from the mold cavity before and during metal injection. This minimizes porosity and improves structural integrity, making it ideal for high-precision and pressure-tight components.

⚙️ How Vacuum Die Casting Works: