Collabration Through DFM

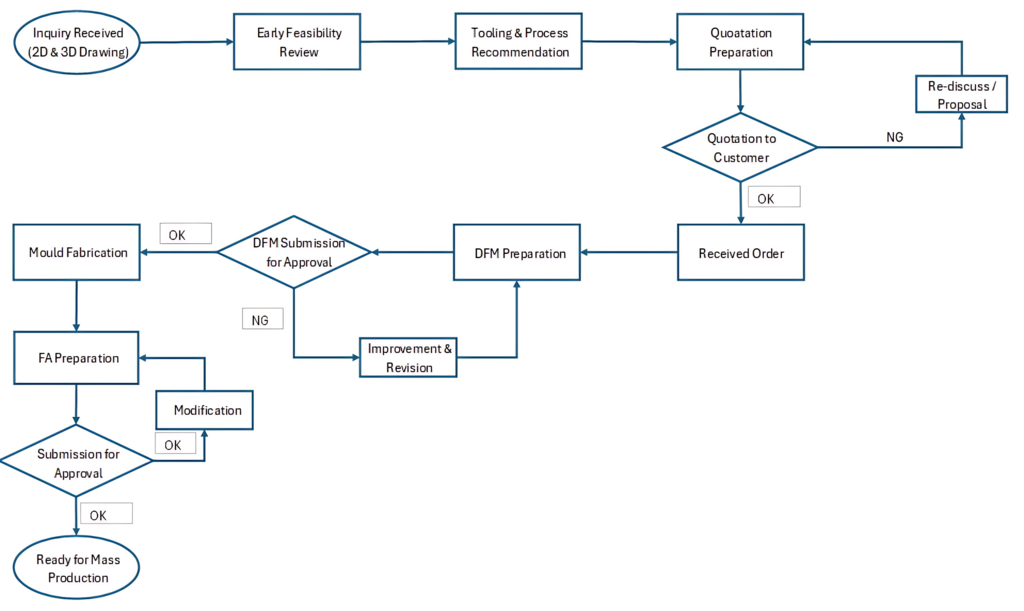

At ZincAlu, we believe the best outcomes begin with early collaboration. That’s why we actively engage our customers through a Design for Manufacturability (DFM) approach at the earliest stages of a new project.

Our experienced engineering team works closely with your designers and product developers to ensure each component is optimized for efficient, cost-effective, and high-quality production.

Initial Quote, analyze part geometry, wall thickness, draft angles, and gating options to ensure the design is casting-friendly.

Offering advices and giving options to cater for most suitable casting method, machine tonnage, and mold design concept for optimal performance and mold life.

We can provide assistance with CAD modeling for accurate 3D models. Upon request, performing mold flow simulations, and results analyze for optimum casting design.

We believe in building strong partnerships with our clients through transparent communication. Your input is essential — actively involve customers/partners in the design process to ensure the final die design aligns with your functional, technical, and cost expectations. Together, we deliver smarter, more effective solutions.